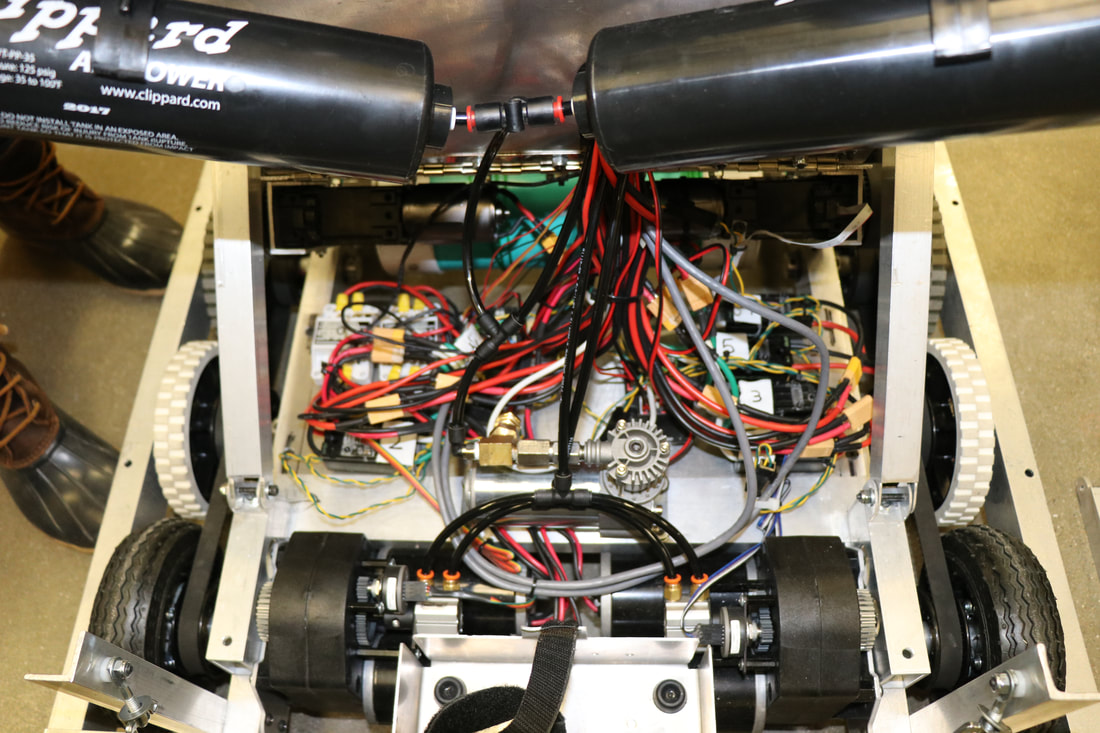

The Electrical Subteam is a small subteam whose job it is to design and build the electrical control and pneumatic systems for the robot. The electrical control system has similar jobs to the nervous and circulatory systems of the human body, it distributes power to all necessary components as well as processing outside information into outputs to be sent to different components on the robot. The pneumatic system uses pressurized air to perform actions. The Electrical Subteam face many challenges, such as finding space to mount larger components, routing wiring and pneumatic plumbing to hard to reach areas of the robot, and organizing the system as a whole.

|

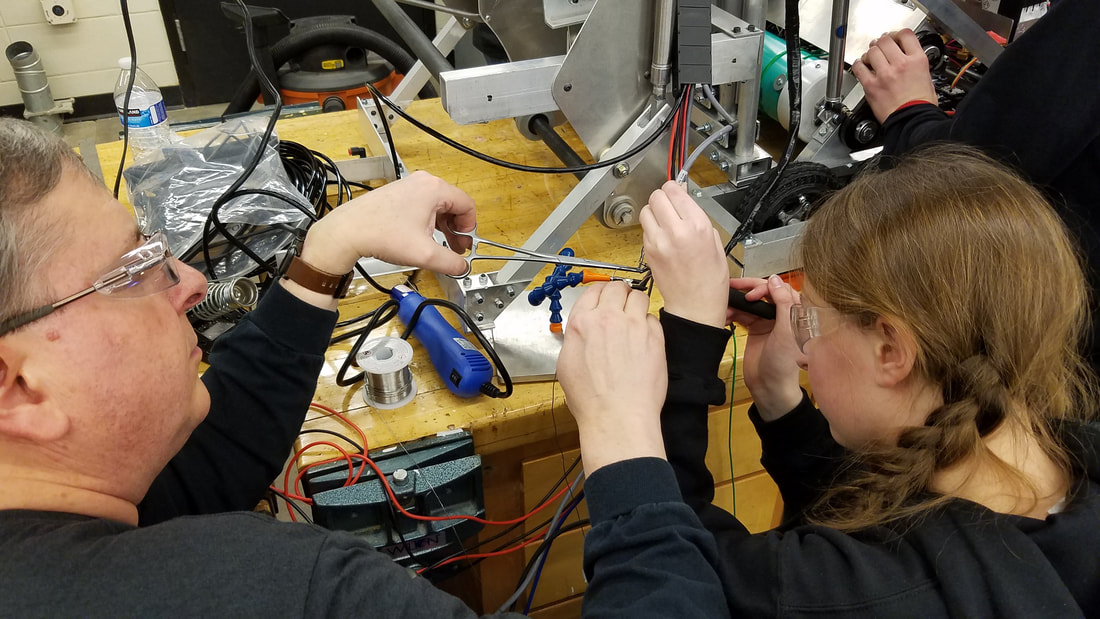

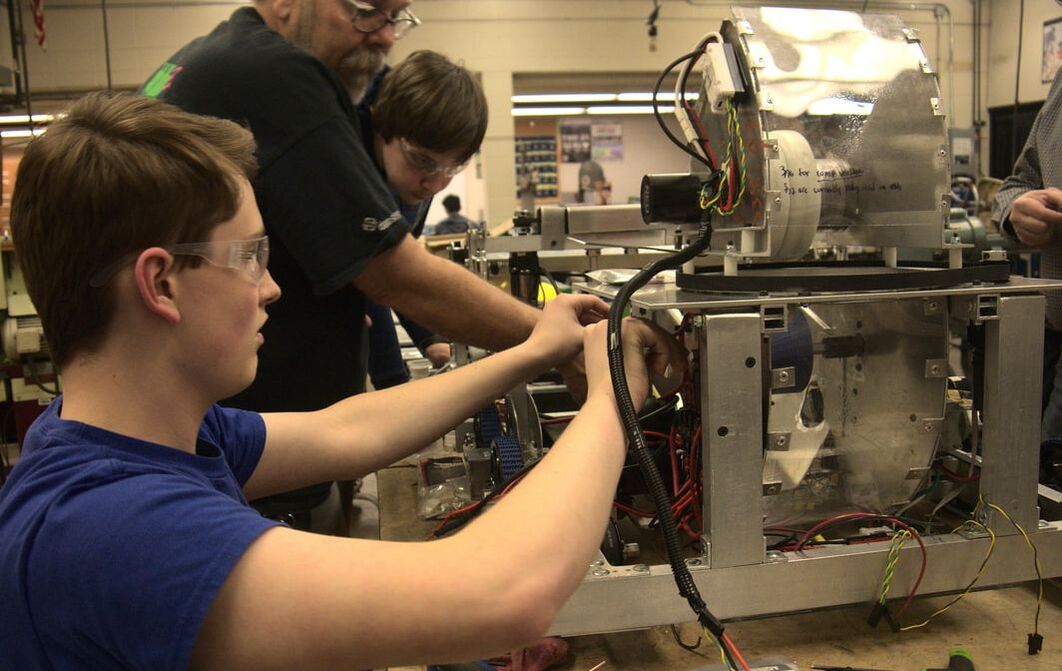

The Electrical Subteam’s job doesn’t come into play until the latter half of the build season, where a more finalized version of the robot must have a control system. At this point, the subteam begins planning where to put major components and how to route wiring and plumbing to different reaches of the robot. Once the Build and Design subteams are mostly done with the robot, the Electrical Subteam begins to build the system. This can involve fabrication of parts to mount components on to, cutting and soldering of wiring and connectors, and wiring and organization of the main control system. During the competition season, the Electrical Subteam has a presence in the repair pits to troubleshoot any electrical or pneumatic issues.

|

In the past, the Electrical Subteam built “Test Boards” that are simple control systems ready to be used to test mock-ups and prototypes. The largest advantage of these test boards is it allows their independence from programming. All motors and actuators are controlled using basic buttons and dials installed onto the board itself. These are most used in our mock-up and prototyping phase, allowing any student to test and iterate on mechanisms using motors and actuators very quickly.