The Build Sub-team is the largest of all of the sub-teams and it’s responsible for the design and manufacturing of the robot as well as having “safety sessions” teaching proper safety procedures when using machinery. The build sub-team is comprised up of multiple smaller teams each responsible for one aspect of the robot; From the drivetrain to the intake mechanism and everything in between. We work together to achieve a common goal, in this case fabricating the robot.

|

At the beginning of each build season, the students come up with a multitude of mechanisms to help achieve what we want our robot to do for that year. This starts with a brainstorming session with 4-7 students and 1-2 mentors to provide input. From the initial ideas, each brainstorming team will select the best idea their group has come up with and recreate their mechanism using wood and then present their ideas to the rest of the team. Afterwards, the team will decide which teams will get the green light to proceed to the metal mockup stage where those wooden versions get replicated into metal versions to help better identify the potential problems that we may face, from potential on-field competition reliability issues to manufacturing complexities that need to be overcome. From here those team will again present their refined metal version to the team. At which point the team will go through each of the mechanisms identifying the advantages and disadvantages of each mechanism and choose which one will become our team's final design and continue into the manufacturing phase.

|

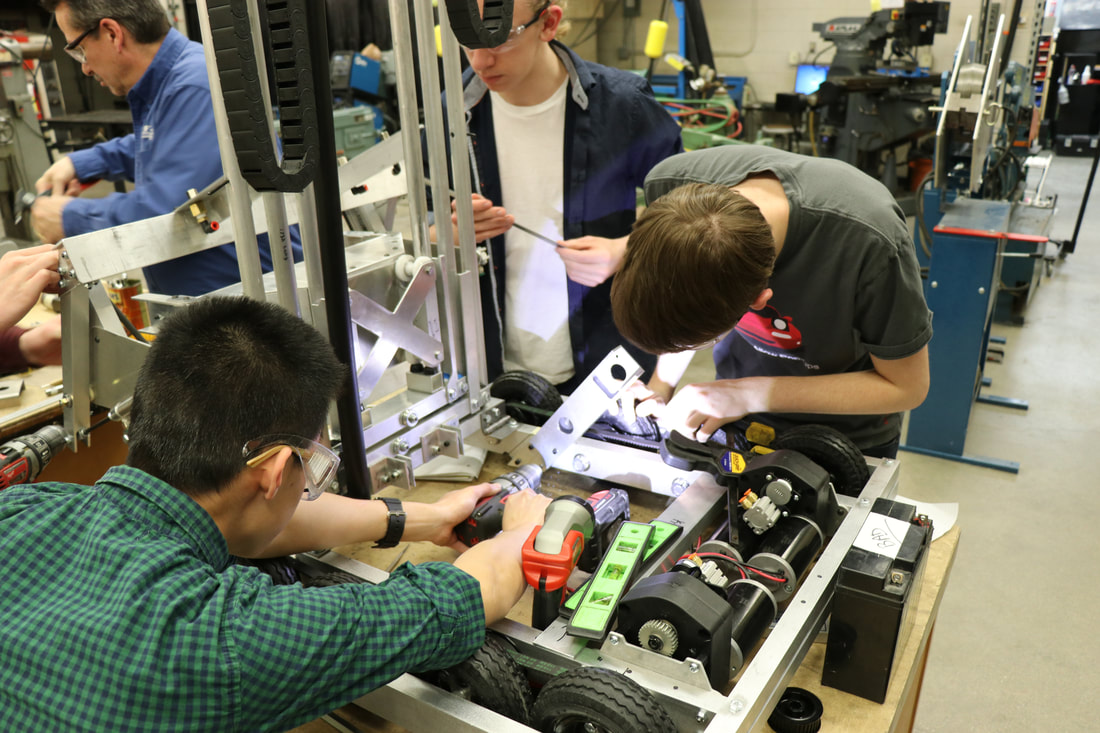

In the manufacturing phase, students will be divided into a sub-team of their choosing. Some of these sub-teams include but are not limited to, lift mechanism sub-team, drivetrain sub-team, Intake sub-team, etc. Each build sub-team will most often create multiple sets of these parts since our team builds two robots each competition season. One that will become our competition robot, that will be exclusively used at competitions and a practice robot which the drive team will use to practice on. Another reason for creating duplicate parts is to have spares for competitions, allowing us to quickly swap out individual parts as needed.

|

Another responsibility the build team as a whole is to work effectively and efficiently while communicating with the other sub-teams like the electrical and code sub-teams allowing them ample space to accommodate their needs like installing the electronic and pneumatic systems as well as providing sufficient time for code to fine-tune their code. Another team we work closely with is the CAD sub-team. We will work together to aid each other with design adjustments and to refine measurement details. In addition, this relationship between the CAD and build sub-teams helps to create less manufacturing errors as well as proving a means to document all of our mechanical work electronically for future reference in other games.

|

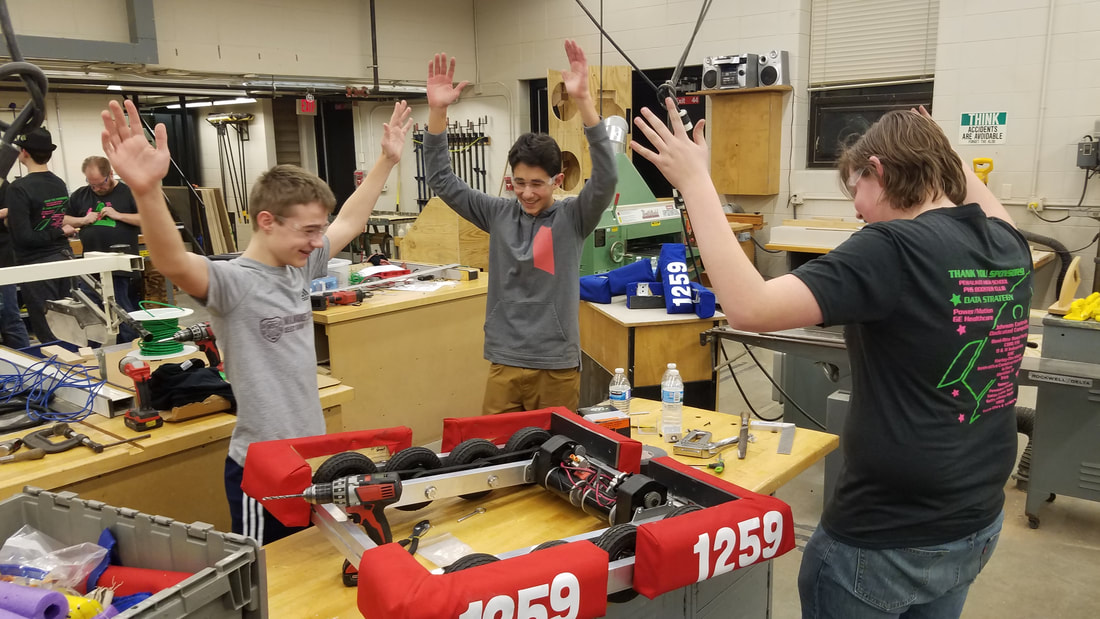

In the summer during the off season, we have weekly meetings to test out different concepts that we would normally have no time for during the build season. Examples would be Swerve drive and West coast drive. During this time we invite new incoming students to interact with our team in a less chaotic environment where existing members can help students learn how to use basic tools as well as interacting with other veteran members allowing for a smoother transition into their first official build season. This time of the year also allows new students to network and get a grasp of what the other sub-teams role may entail, like build, electrical and code teams during the official season. All of this helps to create a stronger foundation and lasting bond between members and to make them feel more welcomed into the entire robotics team.